Xinjiang Kunyu Iron and Steel Co., Ltd.

Release time:

2023-09-20

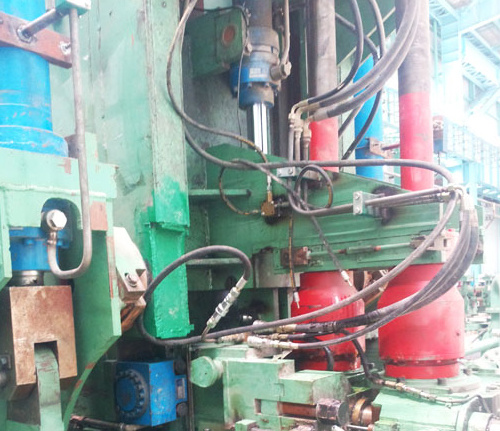

The 600,000-ton high-line oil and gas lubrication system of Kunyu Iron and Steel Co., Ltd. was contracted by Yantai Huashun Mechanical Engineering Equipment Co., Ltd. and was installed in July 2013. It was officially put into full production in August. The equipment manufacturers and lubrication equipment are configured as follows:

1. Coarse-medium-tie and pre-finishing rolling. Among them, the manufacturer of the coarse-medium-tie rolling mill is Shanxi Taikuang, and the manufacturer of the pre-finishing rolling mill is Hafei. The lubrication range is 70 meters. The lubrication parts include: the rolling mill body, the guide guard, the looper, the bracket, etc., a total of 272 lubrication points, and the lubrication equipment is equipped with one main battle, four sub-stations, two sets of external gas source treatment devices, and oil and gas distributors.;

2. The finishing mill adopts imported Morgan rolling mill, with a lubrication range of 20 meters, a guide guard for the lubrication site, 22 lubrication points, and a main battle and imported Wiener oil and gas distributor for the lubrication equipment.;

3. The mini rolling mill adopts imported Morgan rolling mill, the lubrication part is guided, the lubrication points are 2 points, and the lubrication equipment is equipped with a main battle and imported Wiener oil and gas distributor.

Yantai Huashun Oil and Gas Lubrication System

Installation quality: the installation is carried out in strict accordance with the requirements, without affecting other supporting equipment; the quality is qualified, there is no leakage, and the protection is in place to ensure the safe and normal use of the equipment and pipelines.

The effect of using Huashun oil and gas lubrication system: The lubrication effect is good. From the test run to the full-load production, there are no accidents caused by bearing burning or shutdown due to lack of bearing oil. The site is very clean, and the labor intensity of the workers is greatly reduced when the bearings are replaced. Inspection and maintenance are very convenient. Transparent pipes are used at the outlet of the sub-station and the inlet of the lubrication point. The connection is very intuitive. See the status of oil and gas; The operation process is simple and easy to understand, with a high degree of mechatronics, Siemens PLC+Chinese touch screen, easy and intuitive to operate; low equipment failure rate and low inventory of spare parts.

After-sales service: After-sales service is timely and effective, with return visits once a month, timely communication and guidance with customers, and correction of unreasonable use on site, ensuring the normal use of equipment and the normal progress of production.

Previous Page

National Advisory Hotline

Sales Hotline: 18953589385

Fax: 086-535-6890958

Email: wang@ythuashun.com

Address: No.1, Jingba Road, High-tech Zone, Yantai City, Shandong Province

Powered by: 300.cn SEO Tags