Meaning of oil-air lubrication

01

Oil-air lubrication is a typical application of "gas-liquid two-phase fluid cooling lubrication technology", which separates the relative motion friction surface through the formation of gas-liquid two-phase film, so as to play a lubricating role.

02

Compared with the single-phase liquid film, the lubricating film thickness increases, the lubricating film formation rate increases, and the lubricating effect is greatly improved.

03

Simply put, oil-air lubrication is to mix the lubricant and compressed air supplied separately, and form a turbulent oil-air mixed flow, and finally spray the lubrication point in the form of fine oil droplets, which is neither lubricated nor underlubricated.

Basic principles of oil-air lubrication

As shown in Figure 1, in the oil-air lubrication system, compressed air and lubricating oil are mixed to form an oil flow. The compressed air in the pipeline moves at a high speed of 50-80 m/s, and drives the lubricating oil to move forward slowly at a speed of 2-5 cm/s; because the flow speeds of the lubricating oil and the compressed air are very different, the lubricating oil and the compressed air are not Really fused, the lubricating oil is not atomized, so the lubricating oil and the compressed air coming out of the pipeline are also separated.

In the oil-air lubrication system, the intermittent oil supply method is adopted, that is, according to the set working cycle, the system supplies a certain amount of oil at intervals. The interval time and the amount of oil can be adjusted according to the consumption of each lubrication point. It can be quantitatively supplied, but the supply of compressed air is continuous. It is because of the continuous effect of compressed air that the intermittent supply of oil can form a continuous oil film in the pipeline, so as to ensure that the lubricant obtained at the lubrication point is fresh and continuous at all times, and it also ensures that the lubrication point per unit time Get an equal amount of lubricant.

Figure 1: Schematic diagram of oil and gas flow formation

Oil and air lubrication requirements for oil and compressed air

● Different from other lubrication methods, oil-air lubrication is almost not limited by the viscosity of the oil, not only thin oil, semi-flowing dry oil, but also lubricants with a high proportion of solid particles can be successfully supplied. In general, we recommend ISO VG220#-460# high temperature extreme pressure gear oil or synthetic oil.

●Oil-gas lubrication does not require high cleanliness of oil, NAS9 grade or better than NAS9 grade, ordinary new oil can generally be used directly, but in order to prevent accidents, that is, adding waste oil or the new oil itself is not clean enough, so a filter with an accuracy of not less than 40μ should be used for filtration before adding oil.

●The requirement of oil-air lubrication for compressed air is that the working pressure is about 4 ~ 6bar. In the case of a large number of lubrication points, considering that there are many pipelines and the pressure loss is correspondingly large, the working pressure can be appropriately increased; in addition, the water content cannot be too high, because Too much moisture will damage the oil film and harm the bearings, gears and other transmission parts. The oil-air lubrication system is equipped with corresponding compressed air treatment device to filter, remove water and adjust pressure of compressed air.

Applicable occasions of oil and gas lubrication

Oil-air lubrication is suitable for lubrication of rolling bearings, open gears, chains, tracks, wheels, etc., especially for high temperature, high speed, heavy load, very low speed, water or other chemically hazardous fluid erosion occasions.

☆ High temperature condition

Many industrial equipment are operating at high temperature conditions, especially in the metallurgical industry, from sintering, ironmaking, steelmaking to profile or sheet rolling, are accompanied by high temperature; such as sintering machine trolley skateboard, steelmaking continuous casting machine, as well as a variety of heating or heating after rolling processes such as wire, bar, pipe, rail beam, plate, sheet rolling and sheet continuous annealing, hot galvanizing, hot tinning, coating and so on have a lot of equipment in high temperature environment.

Oil-air lubrication uses high-viscosity lubricating oil and provides a gas-liquid two-phase film with sufficient thickness and carrying capacity to the bearing, so that the bearing is in a good lubricated state; at the same time, compressed air overflows from the bearing seat, taking away a lot of heat and reducing the temperature of the bearing.

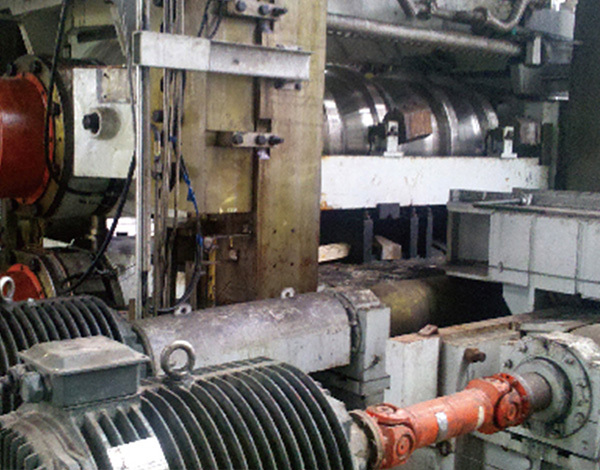

☆ High speed condition

Many industrial equipment are in high-speed operating conditions, such as high-speed wire mill rolling guide bearings, various types of machine tool high-speed spindle.

The gas-liquid two-phase film formed by oil-air lubrication has the dual role of hydrodynamic pressure and hydrostatic pressure; when the speed is high, it can form a complete gas-liquid two-phase film, separating the relative motion of the friction surface, so as to play a lubricating role.

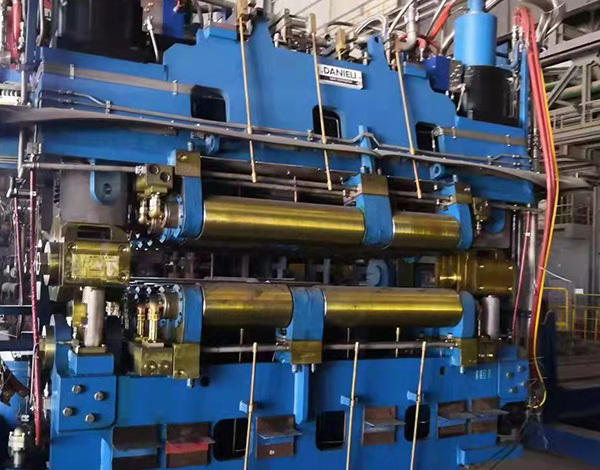

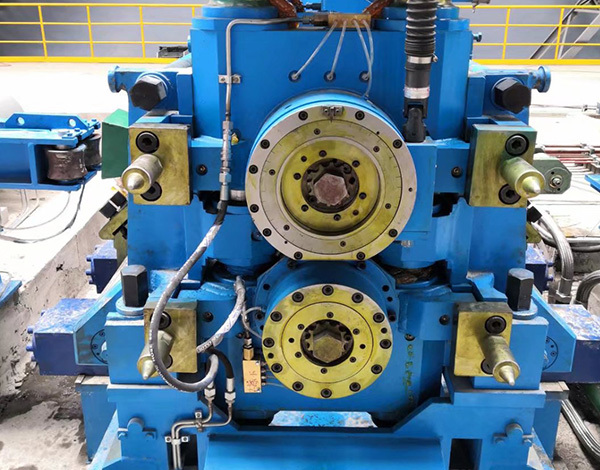

☆ Heavy load condition

Many industrial fields of equipment are in the heavy load conditions of operation, such as strip cold rolling, hot rolling mill, the work roll bearing to bear a huge load, so the lubricant is required to have a high enough viscosity (ISOVG320~680cSt/40 ℃) to achieve a high oil film thickness and oil film formation rate, bearing life is guaranteed.

Oil-air lubrication is almost not limited by the viscosity of oil, not only thin oil, semi-flowing dry oil and even lubricants with a high proportion of solid particles can be supplied smoothly. With the increase of the relative volume content of small air bubbles in the two-phase flow, the lubricating film thickness also increases accordingly, the formation rate of lubricating film is higher, and the carrying capacity is greatly improved compared with single-phase liquid film.

☆ Extremely low speed condition

Many industrial equipment are operating at very low speed conditions, such as slab, billet caster, etc. The gas-liquid two-phase film formed by oil-gas lubrication has the dual functions of hydrodynamic pressure and hydrostatic pressure. When the speed is very low, it can still form a complete gas-liquid two-phase film with strong bearing capacity, so that the friction surface for relative motion is always in good working condition, which is incomparable to the single-phase liquid film formed by hydrodynamic pressure alone.

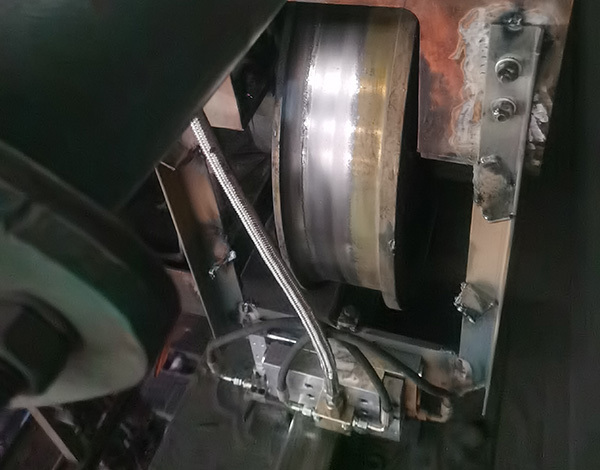

☆ Working conditions eroded by water or other chemically hazardous fluids

Many industrial equipment in the field of water, iron oxide and chemical hazardous fluid erosion conditions, such as strip cold rolling mill need emulsion as a process rolling fluid, bearing seat, especially by the roll neck parts are often washed by emulsion, erosion, harm bearings.

When oil-air lubrication is used for bearings, compressed air overflows from the bearing seat and can maintain a positive pressure of 0.1 ~ 0.3bar in the bearing seat, which can effectively seal the bearing seat and prevent foreign water, harmful gases, iron oxide and other dirt from invading the bearing seat.

Meaning of oil-air lubrication

01

High lubrication efficiency

The gas-liquid two-phase film of oil-air lubrication greatly improves the bearing capacity of the oil film, reduces the friction loss and improves the lubrication efficiency. The lubricant of oil-air lubrication reaches the lubrication point with slow, continuous and uniform trace oil flow. The lubricant obtained by the bearing is fresh all the time, and the gas-liquid two-phase oil film produced by oil and gas is fresh all the time, and the bearing performance is not damaged; the service life of bearings and other transmission parts using oil and gas lubrication is 3 to 6 times that of other lubrication methods, so users can save a lot of spare parts procurement and reserve costs.

02

Low energy consumption

Oil-air lubrication is a fine lubrication method, which can supply as much as it wants, neither lubrication nor lack of lubrication; the consumption of lubricant is only a fraction of oil mist lubrication, and a few tenths of dry oil lubrication., Part of the oil leaked by thin oil lubrication;

03

Wide application

Oil-air lubrication is suitable for lubrication of rolling bearings, open gears, chains, tracks, wheels, etc., especially for high temperature, high speed, heavy load, very low speed, water or other chemically hazardous fluid erosion occasions.

04

Low bearing temperature

Compressed air is a natural coolant, the overflow of compressed air takes away a lot of heat, the bearing can maintain low temperature operation. In some high temperature occasions, the bearing temperature can be reduced by 30~150 ℃, and in cases where the temperature is not too high, the bearing temperature can also be reduced by 10~40 ℃. At the same time, compressed air overflows from the bearing seat and can keep a positive pressure of 0.1 ~ 0.3bar in the bearing seat, which can effectively seal the bearing seat and prevent foreign water, chemically aggressive fluid, harmful gas scale and other dirt from invading the bearing seat and harming the bearing.

05

Fewer moving parts

The oil-air lubrication system has only three moving parts: oil pump, progressive distributor and solenoid valve, so the oil-air lubrication system runs more stably and reliably.

06

Low maintenance costs

The oil and gas lubrication system has low energy consumption, fewer moving parts, and the life of transmission parts. Therefore, the operation and maintenance costs of the lubrication equipment are greatly reduced. In addition to regular cleaning of the air filter element, the high-pressure filter element and adding lubricant to the fuel tank, Basically no other maintenance is required.

07

Concise piping

The pipeline of the oil and gas lubrication system is simple, easy to install and pipe, and there is no special requirement for the direction of the pipeline; it will not be transported from high to low as the oil mist lubrication system, nor will it be necessary to install the return pipe like the thin oil circulation system; and the vast majority of pipelines are low-pressure pipelines (2 ~ 5bar), which are not easy to leak.

08

Small environmental impact

The lubricating oil and compressed air in the oil-air lubrication system are not really integrated, the compressed air is not atomized, the lubricating oil and compressed air from the oil and gas pipeline are also separated, and the compressed air overflowing from the bearing seat basically contains no lubricant. This fully embodies the concept of fine lubrication, how much, how much to give, never lack of lubrication but lubrication, with the minimum amount of lubricant to play the best lubrication effect.

09

Monitoring means perfect, high degree of mechanical and electrical integration

In the oil-gas lubrication system, whether it is oil, gas or oil gas, it can be monitored. The system itself is equipped with a complete PLC control system and an operation panel with a liquid crystal display, which can realize local, remote, test and other modes of operation, and can completely display the operating status and fault information of the system. The system can also provide various display, monitoring and interlocking signals to the control system of the user unit, the degree of mechanical and electrical integration is quite high.

10

Short payback period

The investment recovery period of oil and gas lubrication system is short, and the investment can be recovered from half a year to one year.

Some users of HSH oil-air lubrication technology

Steel users in Northeast China

anshan iron and steel co ltd

Jilin Jianlong Iron and Steel Co., Ltd.

Jianlong Beiman Special Steel Co., Ltd.

Fushun New Iron and Steel Co., Ltd.

Minmetals Yingkou Medium Plate Co., Ltd.

Jilin Xinda Steel Co., Ltd.

Heilongjiang Jianlong Iron and Steel Co., Ltd.

Jianlong Acheng Iron and Steel Co., Ltd.

Jianlong Xilin Steel Co., Ltd.

Lingyuan Iron & Steel Group Co., Ltd.

Jiachen Group (Yingkou) Steel Co., Ltd.

Chifeng Zhongtang Special Steel Co., Ltd.

Steel users in North China

Hegang Co., Ltd. Tangshan Branch

Hegang Co., Ltd. Chengde Branch

Hegang Laoting Steel Co., Ltd.

Chengde Jianlong Special Steel Co., Ltd.

Shanxi Jianlong Industrial Co., Ltd.

Shanxi Taigang Stainless Steel Co., Ltd.

Xinxing Casting Pipe Co., Ltd.

Tianjin Iron and Steel Co., Ltd.

Tianjin Iron Works Co., Ltd.

Hebei Jinxi Iron and Steel Group Co., Ltd.

Tangshan Donghua Iron and Steel Enterprise Group Co., Ltd.

Tangshan Ganglu Iron and Steel Co., Ltd.

Hebei Donghai Special Steel Group Co., Ltd.

Hebei Zongheng Group Fengnan Iron and Steel Co., Ltd.

Tangshan Ruifeng Iron and Steel (Group) Co., Ltd.

Tangshan Guoyi Special Iron and Steel Co., Ltd.

Tangshan Songting Iron and Steel Co., Ltd.

Tangshan Zhengfeng Iron and Steel Co., Ltd.

Xingtai Iron & Steel Co., Ltd.

Shanxi Jinnan Iron and Steel Group Co., Ltd.

Xinzhou Huamao Steel Co., Ltd.

Hejin Hongda Special Steel Co., Ltd

Hebei Xinjin Iron and Steel Co., Ltd.

Handan Iron and Steel Group Co., Ltd.

Hegang Group Shijiazhuang Iron and Steel Co., Ltd.

Xuanhua Iron and Steel Group Co., Ltd.

Luliang Jianlong Industrial Co., Ltd.

Hebei Tangyin Iron and Steel Co., Ltd.

Tangshan Medium Thick Plate Co., Ltd.

Delong Steel Co., Ltd.

Tianjin Tiangang United Special Steel Co., Ltd.

Hebei Wenfeng Industrial Group

Tangshan Yanshan Iron and Steel Co., Ltd.

Qian'an Jiujiang Wire Rod Co., Ltd.

Dedicated Group Limited

Tangshan Donghai Iron and Steel Group Co., Ltd.

Hebei Xinda Iron and Steel Group Co., Ltd.

Qinhuangdao Anfeng Steel Co., Ltd.

Qinhuangdao Baigong Steel Co., Ltd.

Tianjin Rongcheng United Metal Products Co., Ltd.

Xinji City Aosen Iron and Steel Group Co., Ltd.

Shanxi Gaoyi Iron and Steel Co., Ltd.

Shanxi Liheng Iron and Steel Co., Ltd.

Anyang Iron and Steel Group Xinyang Iron and Steel Co., Ltd.

Hebei Wu'an Iron and Steel Group

Xinhui Metallurgical Co., Ltd.

Hebei Yongyang Special Steel Group Co., Ltd.

Steel users in East China

Shagang Group

Shandong Iron and Steel Co., Ltd. Laiwu Branch

Zhongtian Iron and Steel Group Co., Ltd.

Linyi Iron and Steel Investment Group Special Steel Co., Ltd.

Shandong Laiwu Steel Yongfeng Steel Co., Ltd.

Fujian San'an Iron and Steel Co., Ltd.

Weifang Special Steel Group Co., Ltd.

Pingxiang Pinggang Anyuan Steel Co., Ltd.

Jiangyin Huaxi Iron and Steel Co., Ltd.

jiangsu xugang iron and steel group co., ltd

Yancheng Lianxin Steel Co., Ltd.

Shandong Fulun Iron & Steel Co., Ltd.

xuzhou southeast iron and steel industry co., ltd

Anhui Langxi Hongtai Steel Co., Ltd.

Changshu Longteng Rolling Body Manufacturing Co., Ltd.

Fujian Qingtuote Steel Co., Ltd.

Lianyungang Huale Alloy Co., Ltd.

Wuhu Xinxing Casting Pipe Co., Ltd.

Shiheng Special Steel Group Co., Ltd.

Qingdao Iron and Steel Holding Group Co., Ltd.

Shandong Iron and Steel Group Yongfeng Lingang Co., Ltd.

fujian dadonghai industrial group co., ltd

Fujian Sangang Minguang Co., Ltd.

Shandong Chuanyang Group Co., Ltd.

Jiangsu Yonggang Group Materials Trading Co., Ltd.

Changshu Longteng Special Steel Co., Ltd.

Xiwang Special Steel Co., Ltd.

Jiangsu Xindian Steel Industry Development Co., Ltd.

Shandong Luli Steel Co., Ltd.

Anhui Huainan Hongtai Iron and Steel Co., Ltd.

Anhui Shoumine Dachang Metal Material Co., Ltd.

Fujian Luoyuan Minguang Co., Ltd.

Jiangsu Shenyuan Group Co., Ltd.

Jiangsu Yuhua Group Company

Ma On Shan Branch Company Limited

steel users in central china

Hunan Valin Lianyuan Iron and Steel Co., Ltd.

Wuhan Iron and Steel Group Echeng Iron and Steel Co., Ltd.

Anyang Iron and Steel Co., Ltd. Beiguan Branch

Heyuan Derun Steel Co., Ltd.

Hunan Valin Xiangtan Iron and Steel Co., Ltd.

Angang Group Xinpu Co., Ltd.

Henan Jiyuan Iron and Steel (Group) Co., Ltd.

Wuhan Shunle Iron and Steel Co., Ltd.

Steel users in South China

Guangxi Iron and Steel Group Co., Ltd.

Guangdong Shaogang Songshan Co., Ltd.

Guangdong Longchuan Tengda Special Steel Co., Ltd.

Guangxi Wuzhou Jinhai Stainless Steel Co., Ltd.

Qingyuan Caiyuan Hardware Casting Co., Ltd.

Guangxi Shenglong Metallurgical Co., Ltd.

Fogang Dawei Special Steel Co., Ltd.

Guangdong Yueshengxing Iron and Steel Industry Co., Ltd.

Qinzhou Guanggang New Material Co., Ltd.

Qingyuan Taiye Metal Mould Products Co., Ltd

Northwest China steel users

Ningxia Iron and Steel (Group) Co., Ltd.

Shaanxi Longmen Iron and Steel Co., Ltd.

Wuhai Baotou Steel Wanteng Steel Co., Ltd.

Xinxing Cast Pipe Xinjiang Iron and Steel Co., Ltd.

Xinjiang Minxin Iron and Steel (Group)

Minhang Special Steel Co., Ltd.

Shaanxi Iron and Steel Group Hanzhong Iron and Steel Co., Ltd.

Shougang Yili Iron and Steel Co., Ltd.

Xining Special Steel Co., Ltd.

Xinjiang Kunlun Iron and Steel Co., Ltd.

Yili Shouye Dingli Heavy Industry Co., Ltd.

Steel users in Southwest China

Chuanwei Group Chengyu Vanadium Qin Technology Co., Ltd.

Yuxi Xinxing Steel Co., Ltd.

Kunming Julida Steel Co., Ltd.

Yuxi Huixi Metal Casting Products Co., Ltd.

Chongqing Wanda Sheet Co., Ltd.

Sichuan Desheng Group Vanadium Qin Co., Ltd.

Yukun Iron & Steel Co., Ltd. Huixi Branch

Qujing Xin Innovation Material Co., Ltd.

Yunnan Qujing Chenggang Steel (Group) Co., Ltd.

Zunyi Fuxin Special Steel Equipment Manufacturing Co., Ltd.

Non-ferrous industry users

North China Aluminum Co., Ltd

China Color Technology Co., Ltd.

Design Institute Steel User

Sinosteel Engineering Design and Research Institute Co., Ltd.

MCC Jingcheng Engineering Technology Co., Ltd.

Zhongzhi Saidi Engineering Technology Co., Ltd.

Zhongzhi South (Wuhan) Thermal Engineering Co., Ltd.

China Metallurgical Southern Engineering Technology Co., Ltd.

China Heavy Machinery Research Institute Corporation

Dalian Engineering Technology Co., Ltd. Yizhong Group

Priit Gold Technology (China) Co., Ltd.

Shandong Tianzhu Electromechanical Equipment Engineering Technology Co., Ltd.

General contractor of Shandong Metallurgical Design Institute

Shanghai Tianji Zhijin Engineering Technology Co., Ltd.

Shanghai Yaxin Zhijin Equipment Co., Ltd.

Wuxi Qiailian Heavy Engineering Design & Research Institute Co., Ltd.

Sinosteel Equipment Co., Ltd.

Beijing Jingcheng Credit Suisse Long Material Engineering Technology Co., Ltd.

China Metallurgical CCID Equipment Co., Ltd.

Zhongzhi Huatian Nanjing Engineering Technology Co., Ltd.

Zhongzhi Southern Continuous Casting Technology Engineering Co., Ltd.

Xi'an Heavy Technology Co., Ltd.

Erzhong (Deyang) Heavy Equipment Co., Ltd.

Zhongzhi Dongfang Engineering Technology Co., Ltd. Baotou Iron and Steel Design & Research Institute

Shanghai Tianji Zhijin Engineering Technology Co., Ltd.

Shanghai Electric Shangzhong Milling Special Equipment Co., Ltd.

Shanghai Yaxin Continuous Casting Technology Engineering Co., Ltd.

Shanghai Heavy Mine Continuous Casting Technology Engineering Co., Ltd.

Wuhan Comfete General Package

Typical application of oil-air lubrication technology

National Advisory Hotline

Sales Hotline: 18953589385

Fax: 086-535-6890958

Email: wang@ythuashun.com

Address: No.1, Jingba Road, High-tech Zone, Yantai City, Shandong Province

Powered by: 300.cn SEO Tags