HSH-GA-W Intelligent Grease Lubrication System

The intelligent grease centralized lubrication system consists of a remote monitoring host, a main control system, a high-pressure electric pump station, a pressure sensor, automatic grease feeding pumps, grease feeding stations, flow sensors, distributors and connecting pipelines.

- ●The main control system controls the start and stop of the grease station, controls the operation of the electromagnetic feeder, monitors the state of each lubrication point, adjusts the cycle time, adjusts the grease supply of each lubrication point, fault alarm, on-site information collection and remote monitoring.

- ●The high-pressure electric pump station is the heart of the whole system, and the grease is supplied to each lubrication point through the pipeline and the electromagnetic feeder.

- ●The pressure sensor monitors the system pressure in real time and feeds back to the main control system.

- ●The grease feeder in the feeding station is the actuator of the whole system, which controls the opening and closing of the valve to control the grease supply of the lubrication point.

- ●The flow sensor monitors the running state of the lubrication point in real time and feeds back the information to the main control system.

- ●Remote monitoring and control system through wired or wireless information communication.

System composition diagram

Equipment advantages

01

On-time, quantitative and route-by-route oil supply. The whole system only supplies grease to one point at a time, and the grease supply interval time and grease supply amount of each point can be set separately according to requirements.

02

Real-time detection, feedback to the real grease information.The pressure sensor detects the system pressure in real time, and the flow sensor detects the grease supply situation of the lubrication point in real time and feeds back to the main control system in time.

03

Fault location and fault diagnosis.According to the real-time detection, it can accurately locate which point has faults such as blockage and leakage.

04

Remote monitoring, reflecting the real state of oil supply.Remote monitoring can grasp the status of each lubrication point at any time.

05

Suitable for harsh environments. The site equipment is complex and dangerous, and cannot be checked in time during production.

06

System expansion is convenient.Simply adjust the software parameters to increase.

Application Scenarios

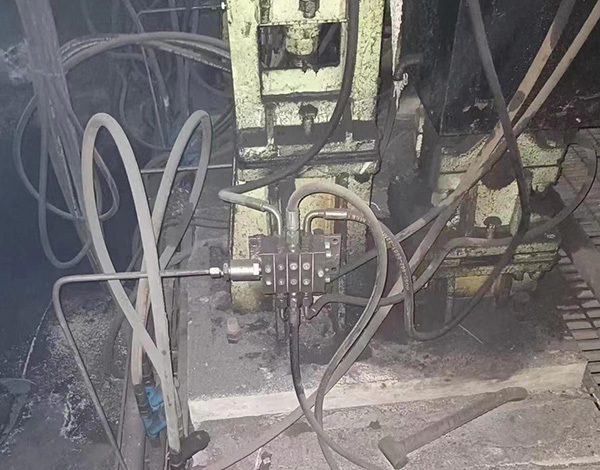

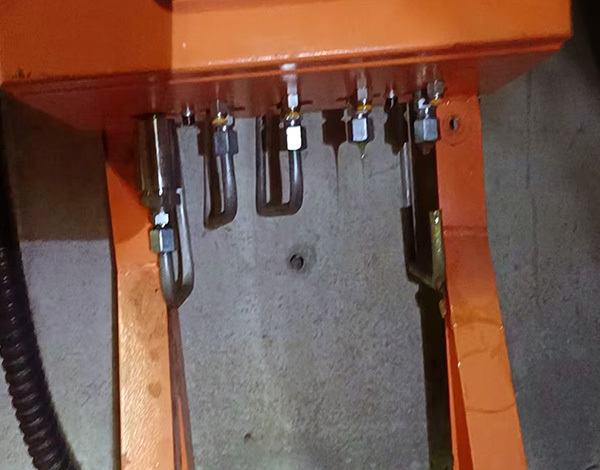

Application Site

Application Site

Application Site

Application Site

Application Site

Application Site

Application Site

Inquiry Hotline

Mob / WA : +86 13365356854

Email: wang@ythuashun.com

Address: No.1, Jingba Road, High-tech Zone, Yantai City, Shandong Province,China

Powered by: 300.cn SEO Tags