Main control system

When supplying oil, the main control program starts the high-voltage electric pumping station in accordance with the set procedure, and the grease is pressed into the main circuit. According to the PLC program and the preset (or user-given instructions) parameters, the corresponding oil feeder gets a signal, opens the solenoid valve, and the grease enters the lubrication point.

Classification:

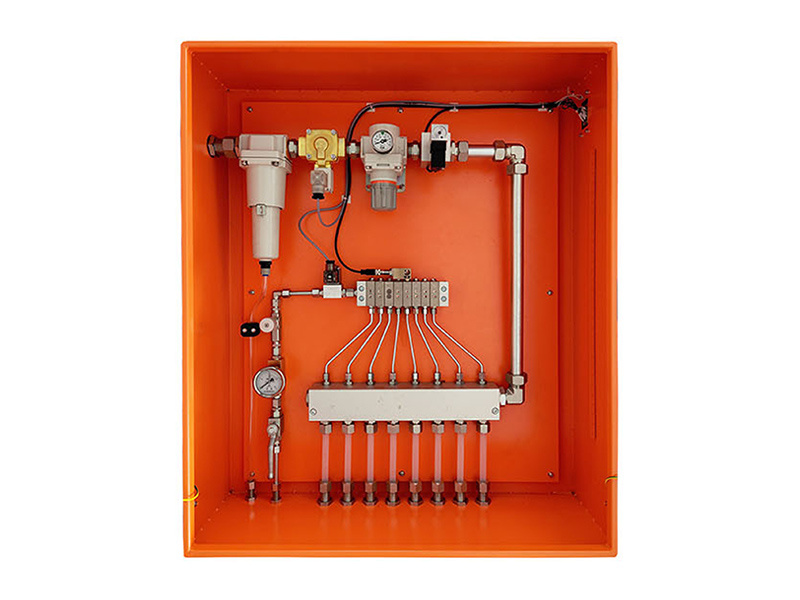

Intelligent Dry Oil Lubrication System

Hotline:

Details

01 When supplying oil, the main control program starts the high-voltage electric pumping station in accordance with the set procedure, and the grease is pressed into the main circuit. According to the PLC program and the preset (or user-given instructions) parameters, the corresponding oil feeder gets a signal, opens the solenoid valve, and the grease enters the lubrication point.

02 At the same time as the oil supply, the flow sensor monitors the lubrication status of the lubrication point, and when there is a failure such as blockage, it immediately sends a fault signal to the PLC, and the PLC records the fault information and alarms.

Equipment advantage

Punctual, quantitative, and route-by-route oil supply

The entire system only supplies oil to one point at a time, and the oil supply interval and oil supply volume of each point can be set separately according to requirements.

Fault location and fault diagnosis

According to the real-time detection situation, it is possible to accurately locate which point there is a fault such as blockage or leakage.

Suitable for harsh environments

The on-site equipment is complex and dangerous, and the parts cannot be inspected in time during production.

Real-time detection, feedback real oil supply information

The pressure sensor detects the system pressure in real time, and the flow sensor detects the oil supply at the lubrication point in real time and feeds it back to the main control system in time.

Remotely monitor and reflect the real oil supply status

Remote monitoring can grasp the status of each lubrication point at any time.

Easy system expansion

Just adjust the software parameters to increase.

Related recommendations

Message consultation

National Advisory Hotline

Sales Hotline: 18953589385

Fax: 086-535-6890958

Email: wang@ythuashun.com

Address: No.1, Jingba Road, High-tech Zone, Yantai City, Shandong Province

Powered by: 300.cn SEO Tags