High temperature crane oil and gas lubrication system

Due to the extremely high surface pressure between the wheels and the track, the pressure resistance of the lubricant must be good, so it is necessary to use lubricants containing a high proportion of solid particles (such as graphite, aluminum powder and other extreme pressure additives) to achieve the ideal lubrication effect.

Classification:

High Temperature Crane Oil and Gas Lubrication System

Hotline:

Details

01 Due to the extremely high surface pressure between the wheels and the track, the pressure resistance of the lubricant must be good, so it is necessary to use lubricants containing a high proportion of solid particles (such as graphite, aluminum powder and other extreme pressure additives) to achieve the ideal lubrication effect.

02 The track lubrication system of the crane is uniquely designed according to the characteristics of the lubricant. The method of oil and gas lubrication for the oil pump can effectively reduce the dry wear between the wheel and the track, and extend the service life of the wheel rim by 2 to 3 times.

03 In some special working conditions, the ambient temperature is high (the instantaneous high temperature can reach 100℃), which will cause fatal damage to all components in the system.

04 To this end, our company has innovatively added a high-temperature air-conditioning system to the crane track lubrication system to ensure the normal operation of the equipment in the high-temperature environment of the steel mill.

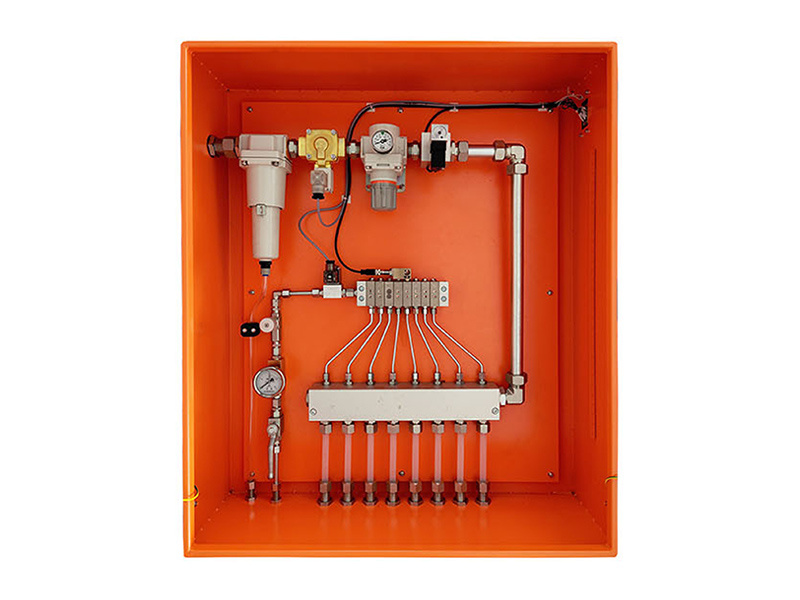

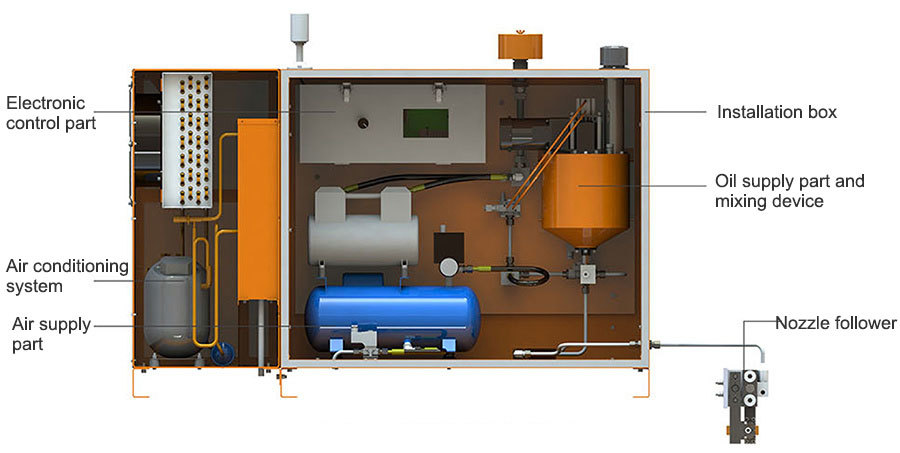

The crane track lubrication system consists of an installation box, an oil supply part, a gas supply part, an air conditioning part, an electronic control part, a stirring device and a nozzle follower device.

■ The box of the crane track lubrication system is divided into two parts. The air-conditioning system (except for the evaporator) is installed in an ordinary single-layer box, the nozzle follower is installed on the wheel bracket, and the rest of the system components are installed in the incubator.

■ Innovative and increased air conditioning system in the crane track lubrication system.The air-conditioning system uses imported high-temperature refrigeration compressors (Taikang), which can operate normally in the high-temperature environment of steel mills.The refrigeration compressor automatically starts and stops according to the temperature parameters set by the system, and its stable operation can provide a suitable temperature for the operation of the system.At the same time, the insulation box equipped with the system provides an auxiliary effect for this effect.

■ The insulation box body is assembled from two layers of steel plates inside and outside, and the interior is equipped with a polyurethane insulation board that can isolate heat. At the same time, a high-temperature-resistant silicone sealing strip is used in the gap between the box body and the door panel, which can also isolate the heat outside the box.The role of the air conditioning system and the insulation box body is combined to ensure that the components in the box body are not damaged by high temperature.

Previous

Next

Previous

Next

Related recommendations

Message consultation

National Advisory Hotline

Sales Hotline: 18953589385

Fax: 086-535-6890958

Email: wang@ythuashun.com

Address: No.1, Jingba Road, High-tech Zone, Yantai City, Shandong Province

Powered by: 300.cn SEO Tags