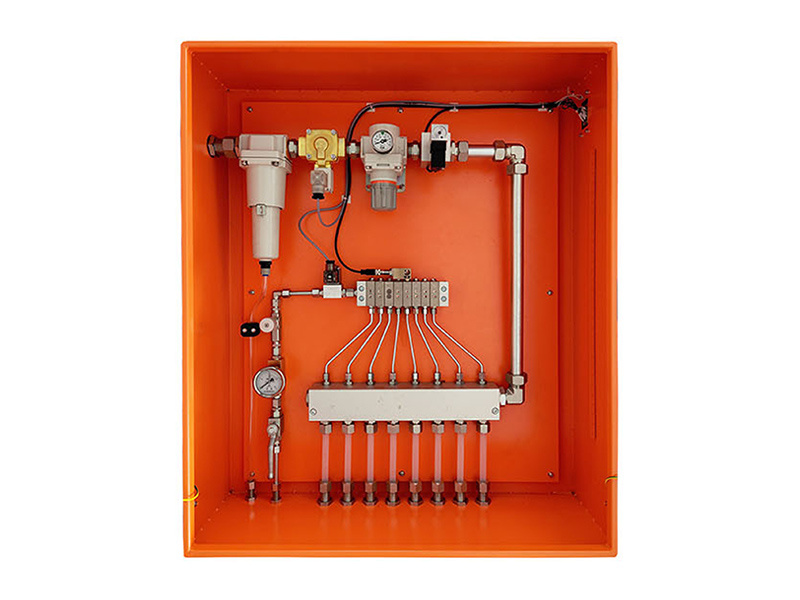

High-voltage electric pumping station

The HSH-GA-W intelligent dry oil centralized lubrication system developed by Huashun can be applied to more than 1000 lubrication points; it is mainly composed of remote monitoring host, main control system, high-voltage electric pumping station, pressure sensor, automatic grease replenishment pump, oil supply station, flow sensor, distributor and intermediate connection pipeline.

Classification:

Intelligent Dry Oil Lubrication System

Hotline:

Details

01 The HSH-GA-W intelligent dry oil centralized lubrication system developed by Huashun can be applied to more than 1000 lubrication points; it is mainly composed of remote monitoring host, main control system, high-voltage electric pumping station, pressure sensor, automatic grease replenishment pump, oil supply station, flow sensor, distributor and intermediate connection pipeline.

02 The lubrication effect of the system is ideal, the operation is stable and reliable, the failure points are easy to find, and the maintenance is small; it is easy to operate and can be remotely monitored, which greatly improves work efficiency and reduces the labor intensity of workers; the oil supply is adjustable to avoid grease waste and environmental pollution. At the same time, it can extend the service life of the equipment and improve the comprehensive benefits.

Main equipment

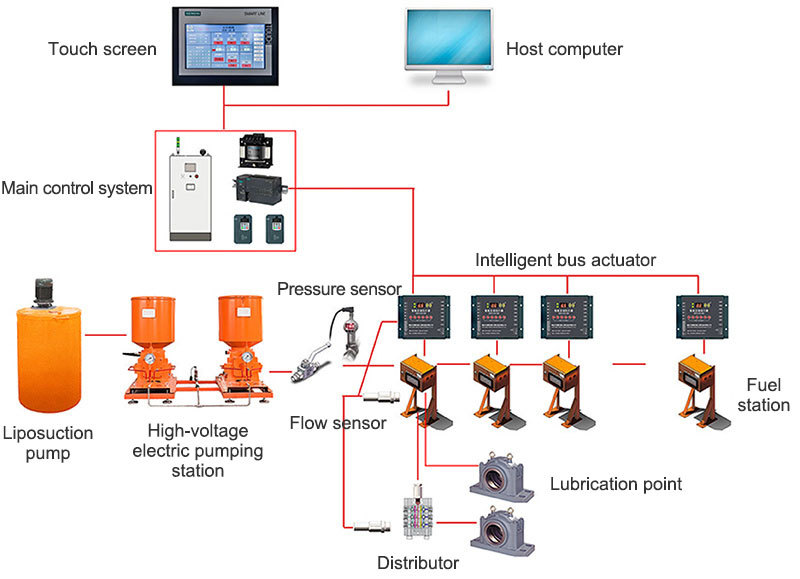

Schematic diagram of system composition

Yantai Huashun HSH-GA-W intelligent dry oil centralized lubrication system consists of a remote monitoring host, a main control system, a high-voltage electric pumping station, a pressure sensor, an automatic grease replenishment pump, an oil supply station, a flow sensor, a distributor and an intermediate connection pipeline.

● The main control system controls the start and stop of the oil station, controls the operation of the electromagnetic oil feeder, monitors the status of each lubrication point, adjusts the cycle time, adjusts the oil supply of each lubrication point, fault alarm, on-site information collection and remote monitoring.

● The high-voltage electric pumping station is the heart of the entire system, and the grease is supplied to every lubrication point through pipelines and electromagnetic oil feeders.

● The pressure sensor monitors the system pressure in real time and feeds it back to the main control system.

● The oil feeder in the oil supply station is the actuator of the entire system, which controls the opening and closing of the oil valve and realizes the control of the oil supply to the lubrication point.

● The flow sensor monitors the operating status of the lubrication point in real time and feeds the information back to the main control system.

● Information communication between remote monitoring and the main control system is realized through wired or wireless.

Previous

Related recommendations

Message consultation

National Advisory Hotline

Sales Hotline: 18953589385

Fax: 086-535-6890958

Email: wang@ythuashun.com

Address: No.1, Jingba Road, High-tech Zone, Yantai City, Shandong Province

Powered by: 300.cn SEO Tags